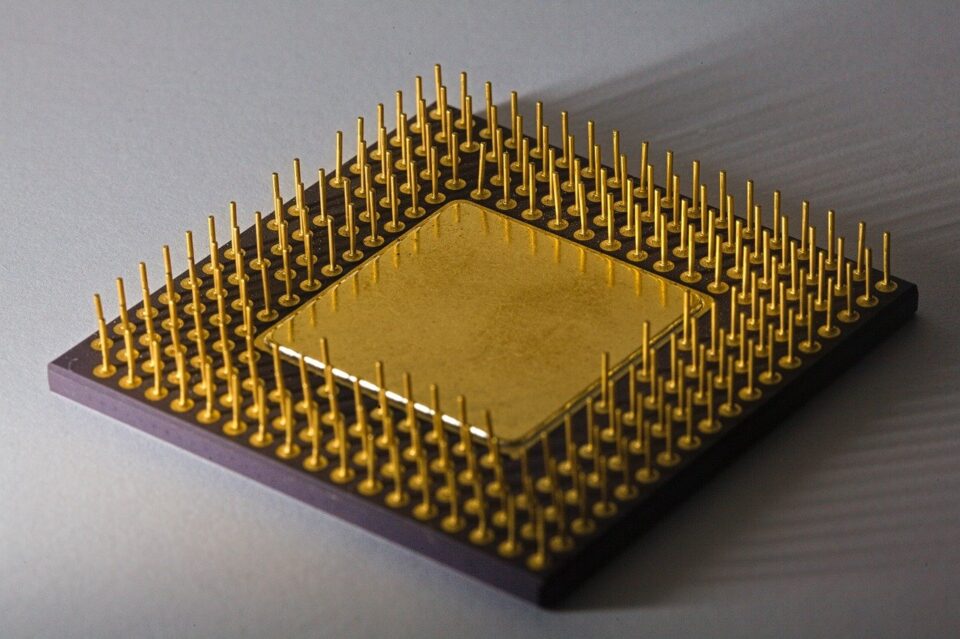

Many people find themselves with old electronics that they want to get rid of, but just where do all those unwanted devices go? Well, once the recycling company has stripped anything valuable from your old cell phone or laptop, it becomes electronic scrap. Electronic scrap is not new on the business world and it’s not limited to computers. From microwaves to radios and televisions, there is a lot of electronic waste piling up globally. But what if you could recover gold from electronic scrap without using any chemicals?

The process is called cold recycling which is similar to recycling at home; however, instead of heating the material up in order to melt out the gold, it is done at room temperature. The process also does not release any toxic substances into the environment like chemicals do. Here’s how cold recycling works.

In the recycling process, electronic scrap is a by-product. Scrap can come from anything from a cell phone to a laptop and is generally made up of plastic, metals and glass.

How Do You Recover Gold From Electronic Scrap?

To start, the cell phone is taken apart and each component is inspected to see what can be reused or resold. This includes anything from batteries to wires. Next, all of the non-gold parts are moved into a massive furnace where they are heated up until they turn into a molten slag. The slag is then cooled which allows it to be cut up into a more manageable size. Once this process is complete, the gold and silver will have been extracted from the slag and can be refined with no chemicals needed!

Many people are not aware but cold recycling can actually produce more gold than traditional methods of mining gold. When you electrocute the metal in a vat of acid, it turns into thousands of small pieces that are then heated to extract the gold. The problem is that when the metal is turned into small shards, it’s very hard to remove all of the acid from them. This means that the gold will still be contaminated with some form of chemicals which is not good for the environment. With cold recycling, they use large pieces of metal so they don’t have this problem.

So what are some other advantages? Not only does it reuse valuable resources, but also cold recycling helps to create jobs and save money on shipping costs. Another advantage is that there’s no need for toxic substances like acids or cyanide, which are often used in traditional mining. This practice can pollute water supplies or cause harm to nearby wildlife depending on how they’re disposed of.

How to Prevent Electronic Waste

Electronic waste is a massive trouble within side the world. So, what are you able to do to save you it? One option is to use cold recycling. Cold recycling doesn’t require any harsh chemicals and releases no toxic substances into the environment. The process of cold recycling is similar to recycling at home; however, instead of heating the material up in order to melt out the gold, it is done at room temperature.

Conclusion

Many people are not aware that gold is often found in electronic scrap. There are several methods of extracting gold from electronic scrap, but the best method is Gold Refining by Cold Recycling.

Cold recycling is the process of melting down all the metals in electronic scrap to produce a homogeneous product that is then cast into an ingot. This produces a higher quality ingot than traditional recycling methods.

The process is much less expensive than refining the metal by traditional means, and it does not require any chemicals.

Electronic scrap is all around us, and there is gold to be found in it.

The goal of this blog post is to educate people on how to find gold in electronic scrap without chemicals.

1. Electronic Scrap Is Anything With An Electronic Chip

2. How Do You Recover Gold From Electronic Scrap?

There are several methods of extracting gold from electronic scrap, but the best method is Gold Refining by Cold Recycling.

Cold recycling is the process of melting down all the metals in electronic scrap to produce a homogeneous product that is then cast into an ingot. This produces a higher quality ingot than traditional recycling methods.

The process is much less expensive than refining.